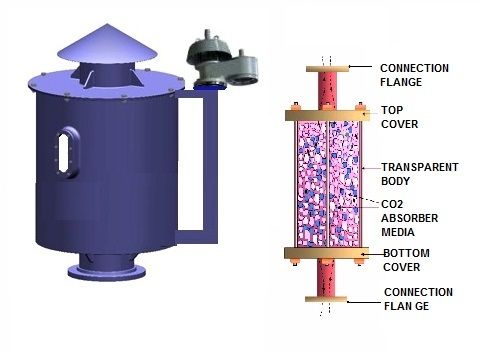

Activated Carbon Absorbers

Product Details:

- Weight 2-5 Kilograms (kg)

- Color Black

- Usage Chemical Industry

- Material Stainless Steel

- Product Type Absorber

- Click to view more

Activated Carbon Absorbers Price And Quantity

- 1 Unit

- 11000.00 - 20000.00 INR

Activated Carbon Absorbers Product Specifications

- 2-5 Kilograms (kg)

- Black

- Stainless Steel

- Absorber

- Chemical Industry

Activated Carbon Absorbers Trade Information

- Cash in Advance (CID) Cheque Cash Advance (CA)

- 10 Unit Per Month

- 3-4 Week

- Yes

- If order is confirmed we will reimburse the sample cost

- Wooden And Carton box

- Australia Eastern Europe Western Europe Middle East Central America Africa South America Asia North America

- All India

Product Description

Fluidyne Activated Carbon absorbers use granular activated carbon (GAC) for removing organic constituents and residual disinfectants in water supplies. This not only improves taste and minimizes health hazards; it protects other water treatment units such as reverse osmosis membranes and ion exchange resins from possible damage due to oxidation or organic fouling. Most activated carbons are made from raw materials such as nutshells, wood, coal and petroleum. Different raw materials produce different types of activated carbon varying in hardness, density, pore and particle sizes, surface areas, and ph. The two principal mechanisms by which activated carbon removes contaminants from water are adsorption and catalytic reduction. Organics are removed by adsorption and residual disinfectants are removed by catalytic reduction. This is usually the case anyway since activated carbon is often used upstream of ion exchange or membranes to remove chlorine. Activated carbon can remove and destroy residual disinfectants (chlorine and chloramines) through a catalytic reduction reaction. Activated carbon absorbers are filters and need to be backwashed periodically.