Breather Valve

Product Details:

- Structure Regulating

- Type Valve

- Power Manual

- Pressure High Pressure kgf/cm2

- Media Water

- Click to view more

Breather Valve Price And Quantity

- 2000.00 - 15000.00 INR

- 1 Unit

Breather Valve Product Specifications

- Water

- Manual

- Valve

- Regulating

- High Pressure kgf/cm2

Breather Valve Trade Information

- Cash in Advance (CID) Cheque Cash Advance (CA)

- 10 Unit Per Month

- 3-4 Days

- Yes

- If order is confirmed we will reimburse the sample cost

- Wooden and Carton Box

- Western Europe Australia Eastern Europe Central America Middle East South America Asia North America Africa

- All India

Product Description

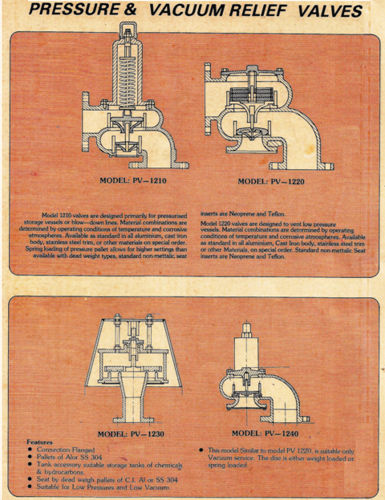

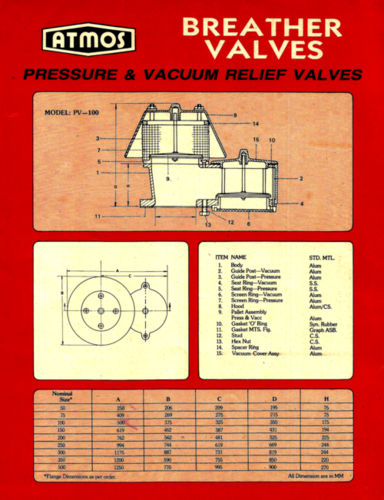

Fluidyne Breather Valves, also known as direct acting Pressure Vacuum Relief Valves, are types of Relief Valves designed for tank protection. The range includes:-

Pressure Vacuum Valve (PV-Valve)

Breather Valve - Pressure only

Breather Valve - Vacuum only

Breather Valve with Flame Arrestor

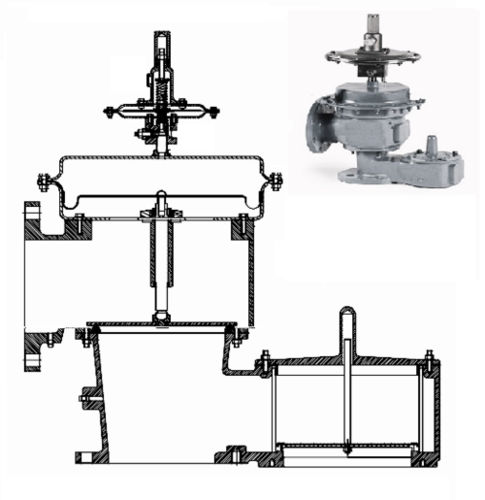

All Fluidyne Breather Valves are available with flanged outlets or vented to atmosphere. Pressure/Vacuum Relief Valves are used mainly on bulk storage tanks, including fixed roof tanks with floating covers, to minimize evaporation loss. The Valves prevent the build-up of excessive pressure or vacuum which can unbalance the system or damage the storage vessel. Pressure and Vacuum protection are controlled with weight loaded pallets or springs loaded disc and the required Pressure/Vacuum settings are reached. Sometimes pressure settings require spring loaded disc and the vacuum settings use weight loaded pallet in one device.

Fluidyne Breather Valves follow American Petroleum Institute Standard API 2000 or other applicable standard where tanks are generally large volume welded vessels that are built to API 650 standard. In order to accommodate large volumes at low set pressures, these Valves have ports that are larger in area than the inlet or nozzle connection. The low setting required generally require weight loaded disc or pallet and sometimes require spring loaded disc. Because of the above, a Breather Valve requires approximately 20% (minimum) to 100% over set pressure in order to reach full opening of the Valve.

DESIGN FEATURES :

| WEIGHT LOADED & SPRING LOADED TYPES | Pressure or Vacuum & Pressure cum Vacuum Types |

| END - OF - LINE WITH WEATHER HOOD OR IN-LINE TYPE. | Breather Valve with Flame Arrestor Emergency Vents for Higher Flow |

| FLANGED OR SCREWED / SOCKET WELD ENDS | Open to Atmosphere or Inlet Outlet Types. |

| DIFFERENT TYPES FOR EVERY APPLICATION | Type Tested as Per API, ASME, CCOE, PESO Standards |

DESIGN CODES

- API- 2000 & API 650

- API 520

- IS 10987

- EN-12874

- ASME SEC-VIII DIV I