Duplex Filter

Product Details:

- Product Type Filter

- Size 15 - 900 NB

- Usage Water and Chemical Filter

- Color Blue

- Condition New

- Material SS 304/316 L

- Shape Round

- Click to view more

Duplex Filter Price And Quantity

- 1 Unit

- 20000.00 - 70000.00 INR

Duplex Filter Product Specifications

- New

- Filter

- SS 304/316 L

- Round

- Blue

- Water and Chemical Filter

- 15 - 900 NB

- 1 Year

Duplex Filter Trade Information

- Letter of Credit (L/C) Cash in Advance (CID) Cheque Cash Advance (CA)

- 10 Unit Per Month

- 3-4 Week

- Yes

- If order is confirmed we will reimburse the sample cost

- Wooden and Carton Box

- Australia South America Western Europe Middle East Central America Africa Asia Eastern Europe North America

- All India

Product Description

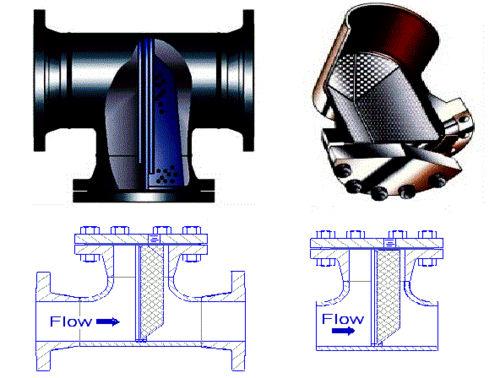

Duplex Strainers

filters, Strainers and pipeline strainer are most commonly used to capture scales, strong particles, dust, sand and so on, which might be hurtful for a few Machines, Valves, Pumps, Blowers, Sprayers, Gas and Oil injectors, Compressors, Bearings, Burners and so on. These advanced strainers and filters likewise are beneficial to avoid contamination to medications, food and process liquids.

Working under extreme conditions, our strainers, pipeline strainers, mechanical pipeline strainers, modern strainers and filters are inventively designed to work successfully furthermore offer high toughness. We have exceptionally trained and experienced designing team who can choose and inventively plan the most suitable strainers for any industry.

Superiority of Our Strainers

Our Strainers are made from top notch castings from reputed Fabricated strainers utilizing consistent pipes. Tried with D.P., Ultrasonic and X-Ray and Radiography, our castings and welds are exceptionally safe to utilize. Test bar study of heat numbers is done for chemical and physical properties. Strict and preventive stage-wise investigations are done with hydaulic testing at 1.5 to 2 times working pressure. Our Strainers are outlined exceptionally to better than others. A few attributes that make them better are mentioned below:

Superbly streamlined flow profiles.

Substantial free flow area to suit huge size of cross section.

Better alteration, less stopping up and tow pressure drop.

Can without much of a stretch withstand change in pressure, vibration and heating impacts.

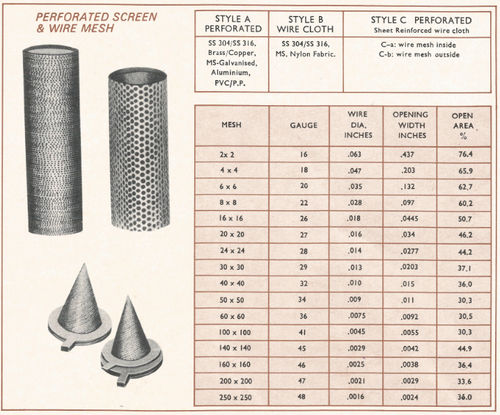

Our Strainers covers Conical Strainer, Y-Strainer,, Duplex Strainer, Pot/Bucket Strainer, Angle Strainer and Tee Strainer. Network from 6 x 6 to 250 x 250. Materials: graded Cast Iron, Steel, Bronze, SS 304, SS 316, Flanged, Screwed and Butt weld, Forged bar stock strainers are provided up to 1500 P.S.I.

Our Strainers are outlined exceptionally keeping in mind their area in a pipeline, application, upkeep requirements and the level of filtration they will be required to do. Spread and baskets bin are exceptionally designed for simple expulsion and cleaning. Drain fittings are given to brush off amassed foreign particles. Drain valves can be provided if it is demanded by clients. For big sized pumps lifting eye jolts or drags are offered to give additional support. To demonstrate the genuineness of our pumps we can likewise give material authentications, Hydro test results and outsider investigation certificate.

| Pressure Drop in (PSI) | ||||||||||||

| L.P.M. | 20 | 25 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

| 25 | 0.125 | | | | | | | | | | | |

| 50 | 0.410 | 0.25 | 0.10 | | | | | | | | | |

| 75 | 1.200 | 0.50 | 0.18 | | | | | | | | | |

| 100 | 2.00 | 1.00 | 0.30 | 0.13 | | | | | | | | |

| 150 | | 2.00 | 0.60 | 0.26 | 0.10 | | | | | | | |

| 200 | | 4.00 | 1.00 | 0.43 | 0.17 | | | | | | | |

| 300 | | 7.00 | 2.00 | 0.90 | 0.33 | 0.17 | | | | | | |

| 400 | | | 3.50 | 1.50 | 0.60 | 0.30 | | | | | | |

| 500 | | | 5.00 | 2.80 | 0.90 | 0.43 | 0.12 | | | | | |

| 600 | | | 8.00 | 3.5 | 1.30 | 0.65 | 0.17 | | | | | |

| 800 | | | | 5.0 | 2.00 | 1.00 | 0.27 | 0.13 | | | | |

| 1000 | | | | | 3.5 | 1.70 | 0.45 | 0.25 | 0.12 | | | |

| 2000 | | | | | | 5.50 | 1.70 | 0.90 | 0.40 | 0.20 | | |

| 4000 | | | | | | | 6.00 | 3.30 | 1.50 | 0.80 | 0.25 | 0.15 |

| 6000 | | | | | | | | 7.00 | 3.00 | 1.50 | 0.50 | 0.25 |

| 8000 | | | | | | | | | 4.5 | 2.50 | 0.70 | 0.40 |

| 10000 | | | | | | | | | | 8.00 | 3.50 | 2.50 |

| 20000 | | | | | | | | | | | | 5.70 |

Dimension Data

| Model & Type | Size | |||||||||||||

| |

| 15 | 20 | 25 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 |

| FY-100 Y-Type Flanged | A | 130 | 150 | 160 | 200 | 230 | 300 | 310 | 350 | 400 | 480 | 600 | 730 | 850 |

| B | 65 | 80 | 110 | 150 | 175 | 210 | 250 | 275 | 310 | 350 | 425 | 500 | 575 | |

| FY-120 Y-Type Screwed | A | 85 | 100 | 120 | 160 | 200 | 250 | 275 | | | | | | |

| B | 50 | 65 | 75 | 100 | 150 | 175 | 200 | | | | | | | |

| FT-110 TEE-Type | A | | | | | 125 | 150 | 170 | 210 | 250 | 300 | 350 | 450 | 500 |

| Al | | | | | 250 | 300 | 310 | 350 | 425 | 650 | 550 | 600 | 750 | |

| B | | | | | 150 | 170 | 180 | 200 | 250 | 250 | 300 | 350 | 400 | |

| FBC-200 FBF-210 Bucket type cast & fabricated | A | | | 175 | 200 | 225 | 300 | 310 | 350 | 400 | 500 | 600 | 750 | 850 |

| B | | | 175 | 200 | 225 | 265 | 300 | 340 | 400 | 450 | 580 | 650 | 750 | |

| FS400 Bucket Separators | A | 200 | 200 | 250 | 275 | 320 | 400 | 400 | 450 | 500 | 500 | 550 | 650 | 650 |

| B | 130 | 130 | 140 | 140 | 150 | 275 | 275 | 325 | 300 | 350 | 450 | 500 | 600 | |

| Bl | 60 | 60 | 60 | 90 | 100 | 125 | 125 | 150 | 150 | 200 | 200 | 250 | 250 | |

| FC 500 Conical Strainer | | | | | 80 | 100 | 120 | 130 | 175 | 200 | 220 | 275 | 340 | 400 |

| | | | | 100 | 115 | 140 | 165 | 200 | 250 | 330 | 430 | 500 | 650 | |

- 'Y' Type, Bucket, 'T' and Duplex.

- For Gas, Vapours, Liquids and Steam.

- Low pressure drop, streamlined body.

- Cast and Fabricated design.

- Baskets of wire mesh/perforated screen.

- Screens of S.S., Brass, Monel, etc.