Excess flow check valves

Product Details:

- Product Type Flow Check Valve

- Structure Plug

- Type Valve

- Media Gas

- Click to view more

Excess flow check valves Price And Quantity

- 8000.00 - 12000.00 INR

- 1 Unit

Excess flow check valves Product Specifications

- Flow Check Valve

- Plug

- Gas

- Valve

Excess flow check valves Trade Information

- Cash in Advance (CID) Cheque Cash Advance (CA)

- 10 Unit Per Month

- 3-4 Week

- Yes

- If order is confirmed we will reimburse the sample cost

- Wooden and Carton Box

- Western Europe Australia Eastern Europe Middle East Africa South America Asia Central America North America

- All India

Product Description

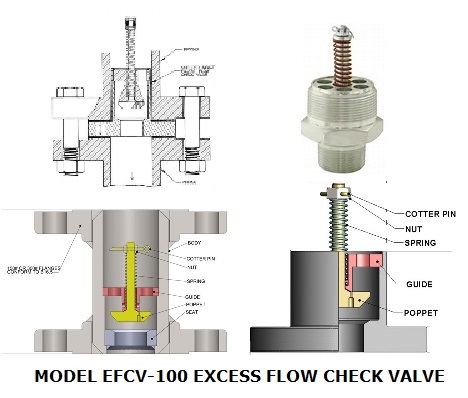

FLUIDYNE EXCESS FLOW CHECK VALVE [MODEL : EFCV-100]

FLUIDYNE Excess Flow Check Valve also called FLUIDYNE Burst Control Valve or FLUIDYNE Hose Safety Check Valve or FLUIDYNE Velocity Check Valve. The valve has a sliding poppet within a chamber with an orifice at one end, wherein the closing flow rate settings can be adjusted. Precise adjustments can be made externally by turning an adjustment nut against a threaded screw extending at the end of the valve which causes a poppet to move within the chamber. As the poppet is urged toward the retainer by a coiled spring, the poppet is moved longitudinally within the chamber, either toward or away from the orifice. Turning the threaded nut enables to adjust the tension on the spring and therefore, the threshold flow rate of the valve could be precisely set. The valves operate by using the pressure differential across the valve to operate the poppet and spring assembly. The pressure differential is directly related to the flow of (SCFM) through the valve. When the pressure differential is within the operating limits - below the cutoff flow - of the unit, the force on the valve exerted by the spring is greater than that caused by the pressure differential the valve remains open and normal operation continues. When the pressure differential is above the cutoff limit, the force on the valve poppet exerted by the pressure differential is greater than the force exerted by the spring, and the valve closes. After the repairs to the line are made, normal operation is automatically enabled when pressure across the valve equalizes through the bleeder hole. The valve spring size can be specified by determining the air flow during normal operation and by estimating the flow if a failure or rupture occurs. FLUIDYNE Excess Flow Check Valve is used in filling lines and protects the system against excess flow rates and safely shuts off the flow due to hose bursts or excessive leakages downstream of the valve. FLUIDYNE Excess Flow check Valves are available in Standard Sandwich types suitable for mounting between a pair of flanges and also flanged screwed or butt weld connections types as per client requirements.

Size Range: | from " (6 mm) to 16" (400mm) |

Pressure Range: | from 2 psi (0.15 bar) to 9000 psi (620 bar) |

Connections: | Threaded / Screwed / Flanged , Wafer (Sandwich) , Butt & Socket Weld & Specials. |

Materials: | Stainless Steel , Carbon Steel , Brass , etc. |

|

|

Standard Flow Settings

Size | Cut-off Flow Rate |

| Size | Cut-off Flow Rate |

1/4" | 23-29 | 1-1/4" | 260-290 | |

3/8" | 39-47 | 300-340 | ||

52-65 | 440-500 | |||

1/2" | 70-78 | 570-630 | ||

80-96 | 1-1/2" | 300-360 | ||

3/4" | 72-88 | 470-530 | ||

92-108 | 640-720 | |||

112-128 | 750-830 | |||

132-148 | 2" | 510-590 | ||

160-180 | 725-825 | |||

180-200 | 900-1050 | |||

1" | 165-195 | 1100-1200 | ||

220-260 | 3" | 1200-1400 | ||

280-320 | 2400-2700 | |||

310-340 | 2850-3050 |