Silica gel Absorbers / Silica Gel Breathers

Product Details:

- Material PVC

- Usage Moisture Removal

- Product Type Breather and Absorber

- Color Blue

- Application Transformer

- Click to view more

Silica gel Absorbers / Silica Gel Breathers Price And Quantity

- 1 Unit

- 450.00 - 1200.00 INR

Silica gel Absorbers / Silica Gel Breathers Product Specifications

- Transformer

- PVC

- Breather and Absorber

- Moisture Removal

- Blue

Silica gel Absorbers / Silica Gel Breathers Trade Information

- Cash in Advance (CID) Cheque Cash Advance (CA)

- 10 Unit Per Month

- 3-4 Week

- Yes

- If order is confirmed we will reimburse the sample cost

- Wooden And Carton box

- Australia Western Europe Middle East Central America Africa South America Asia Eastern Europe North America

- All India

Product Description

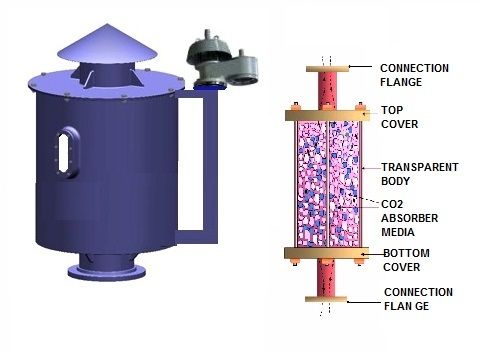

FLUIDYNE Silica Gel Breathers or Desiccants' clean and dry the incoming air. Expelled air partially regenerates the silica gel and back flushes the breather extending the life of the breather. FLUIDYNE Breathers are rugged in construction made of impact resistant Plexiglas, Die Cast Aluminum, Stainless Steel, Plastics and Carbon steel. Silica gel is inert, non toxic and non corrosive and contains microscopic pores that absorb moisture up to 40% to 45 % of its weight (Silica gel as hydrophilic agent.). When silica gel gathers maximum moisture it changes color when it is time to replace or regenerate the silica gel. Industry spends millions annually treating the negative effects of contamination caused by wet, dirty air. This causes contamination of tank contents, lubricants and hydraulic fluids resulting in loss, excess machine wear, production downtime, repair costs, etc. FLUIDYNR Breathers are the perfect solution for high humidity and high dust environments. To extend the desiccant's life a special design incorporates two check valves or inlet oil seal arrangement. The check valves provide a closed system until airflow is required, extending the service life of the desiccant. Specifically, the intake check valve allows airflow into the breather only when differential pressure between the atmosphere and fluid reservoir exceeds a 0.1 psi threshold, while the exhaust check valve permits air to exit the reservoir when the differential pressure exceeds a 2.0 psi threshold. A 0.1 psi check valve is also available for exhaust.

Dimension Information :

| MODEL NO | TANK CAPACITY m3 | Recommended Conn Size | Media Weight (kg) | Flow Rate (m3/HR) | Size Container (Body) (mm mm) |

| SGB 75A | 1.0 | 0.25 | 60 | 75 100 | |

| B | 1.6 | 0.40 | 60 | 75 150 | |

| C | 2.0 | 0.50 | 50 | 75 200 | |

| D | 3.0 | 1 | 0.75 | 50 | 75 300 |

| SGB 100A | 3.0 | 1 | 0.75 | 120 | 100 100 |

| B | 4.0 | 1 | 1.00 | 110 | 100 150 |

| C | 6.0 | 1 | 1.50 | 100 | 100 200 |

| D | 9.0 | 1 | 2.25 | 80 | 100 300 |

| SGB 150A | 7.0 | 2 | 1.75 | 250 | 150 150 |

| B | 9.0 | 2 | 2.25 | 240 | 150 200 |

| C | 12.0 | 2 | 3.00 | 220 | 150 250 |

| D | 14.0 | 2 | 3.50 | 200 | 150 300 |

| SGB 200A | 16.0 | 3 | 4.00 | 450 | 200 200 |

| B | 25.0 | 3 | 6.00 | 440 | 200 300 |

| C | 35.0 | 3 | 8.00 | 360 | 200 400 |

| D | 50.0 | 3 | 12.00 | 300 | 200 600 |

| SGB 250A | 60.0 | 5 | 15.00 | 400 | 250 200 |

| B | 75.0 | 5 | 18.00 | 500 | 250 300 |

| SGB 300A | 100.0 | 4 | 20.00 | 675 | 300 450 |

| B | 150.0 | 4 | 27.00 | 560 | 300 600 |

| SGB 400A | 200.0 | 6 | 50.00 | 995 | 400 600 |

| B | 275.0 | 6 | 66.00 | 750 | 400 800 |

| SGB 500A | 400.0 | 6 | 96.00 | 1350 | 500 750 |

| B | 500.0 | 6 | 128.00 | 1000 | 500 1000 |

| SGB 600A | 550.0 | 8 | 130.00 | 1950 | 600 700 |

| B | 750.0 | 8 | 185.00 | 1400 | 500 1000 |

| SGB 800A | 1250.0 | 10 | 330.00 | 3000 | 800 1000 |

| B | 1600.0 | 10 | 390.00 | 2500 | 800 1200 |