Special Pressure Vacuum Relief Breather Valves

Product Details:

- Product Type Vaccum Relief Valve

- Structure Control

- Type Valve

- Pressure High Pressure kgf/cm2

- Media Gas

- Click to view more

Special Pressure Vacuum Relief Breather Valves Price And Quantity

- 1 Unit

- 8650.00 - 10000.00 INR

Special Pressure Vacuum Relief Breather Valves Product Specifications

- Control

- High Pressure kgf/cm2

- Vaccum Relief Valve

- Gas

- Valve

Special Pressure Vacuum Relief Breather Valves Trade Information

- Cash in Advance (CID) Cheque Cash Advance (CA)

- 10 Unit Per Month

- 3-4 Week

- Yes

- If order is confirmed we will reimburse the sample cost

- Wooden and Carton Box

- Australia South America Eastern Europe Western Europe Middle East Central America Africa Asia North America

- All India

Product Description

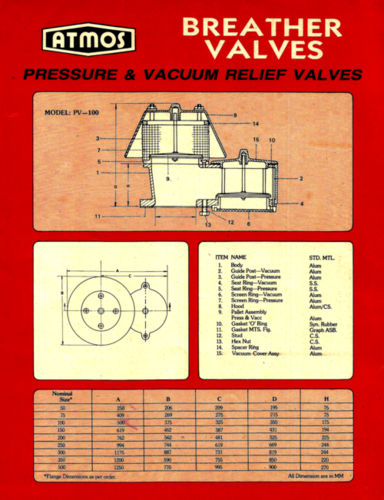

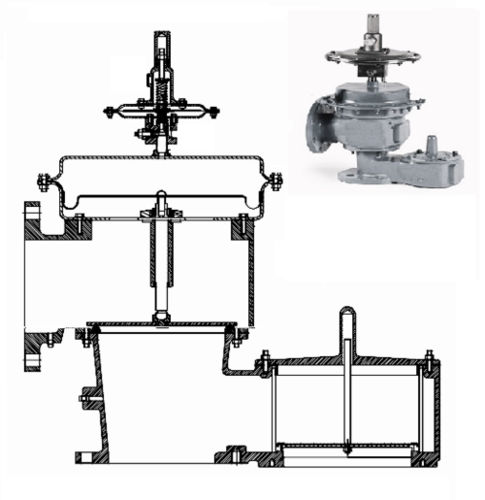

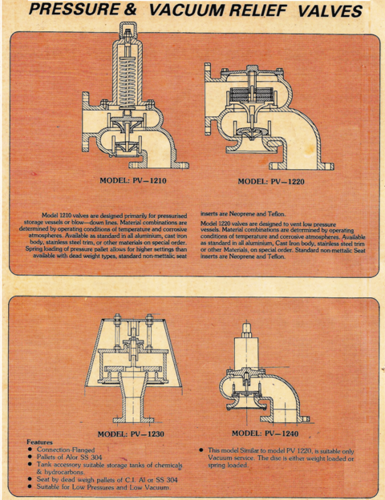

Fluidyne Model 1210 Breather Valves are developed mainly for blow-down lines or pressurized storage vessels. External atmospheric conditions like temperature and corrosive air determine the material combination for these valves. Higher settings then most dead weight types is achieved by spring loading of pressure pallets. Standard non-metallic seat inserts are made using Neoprene and Teflon material. This range of valves are available using pure aluminum, cast carbon steel, stainless steel and cast iron body with stainless steel or bronze trim. They can also be made from other materials on special order.

Fluidyne Model PV 1220 Breather Valves are developed mainly for lower pressurized storage vessels. External atmospheric conditions like temperature and corrosive air determine the material combination for these valves. Lower settings where dead weight pallet types is used. Standard non-metallic seat inserts are made using Neoprene and Teflon material. This range of breather valves are available using pure aluminum, carbon steel, stainless steel or cast iron body with stainless steel or bronze trim. They can also be made from other materials on special order.

Fluidyne Model 1230 Breather Valves are developed mainly for atmospheric low pressure tanks. There is a single disc for both pressure and vacuum. The pressure and vacuum settings available are low. Standard non-metallic seat inserts are made using Neoprene and Teflon material. This range of valves are available using pure aluminum, cast carbon steel, stainless steel and cast iron body with stainless steel or bronze trim. They can also be made from other materials on special order.

Fluidyne Model PV 1240 Vacuum Relief-Breather Valves are developed mainly for higher vacuum settings for storage vessels. External atmospheric conditions like temperature and corrosive air determine the material combination for these valves. Higher variable settings with spring loaded pallet is used. Standard non-metallic seat inserts are made using Neoprene and Teflon material